CNC turning meets the strict precision standards of the medical device industry by utilizing computer-controlled tool paths to achieve micron-level tolerances and superior surface finishes on biocompatible materials. For engineers and procurement managers seeking reliable manufacturing, professional CNC turning services provide the necessary repeatability and quality assurance required for life-critical applications like surgical instruments and orthopedic implants. While many US-based firms initially search for local providers using terms like CNC turning services savannah or CNC turning services georgia, expanding the search to specialized global partners often reveals superior scalability and advanced capabilities for complex medical components.

Advancing Production Efficiency via CNC Turning and Milling Services

Modern medical manufacturing demands the integration of turning and milling to handle complex geometries without compromising speed or accuracy. This dual capability allows for the production of intricate features in a single setup, significantly reducing lead times.

Handling Complex Geometries with Multi-Axis Capabilities

Medical devices, such as bone screws and endoscopic tools, often feature complex geometries that require more than standard 3-axis machining. Advanced CNC turning and milling services utilize 5-axis machines to execute variable thread pitches and intricate contours in one continuous operation. For instance, manufacturing a titanium (Ti6Al4V) bone screw requires maintaining thread profile tolerances within ±0.005 mm while ensuring the core diameter remains consistent to prevent fatigue failure. Multi-axis centers allow tools to approach the workpiece from virtually any angle, enabling the creation of undercuts and off-center features that are impossible with conventional turning alone. This capability is critical for producing spinal implants where the locking mechanism geometry must be precise to micron levels to ensure surgical success.

Reducing Accumulative Errors via Mill-Turn Integration

The integration of milling and turning into a single machine cycle is a game-changer for medical device precision. In traditional workflows, moving a part from a lathe to a mill introduces fixturing errors, often accumulating deviations of 0.02 mm or more. By utilizing mill-turn centers, manufacturers maintain a single datum reference point throughout the process. This “Done-in-One” approach is vital for components like surgical robotics joints, where concentricity and perpendicularity are paramount. Data from manufacturing studies indicates that single-setup machining reduces dimensional variation by over 40%, ensuring that mass-produced parts maintain the same rigorous quality as the initial prototype. This stability is essential for high-volume orders of disposable surgical tools, where every unit must perform flawlessly.

Adherence to Medical Standards and Rigorous Quality Control

In the medical sector, precision is synonymous with patient safety. Manufacturers must implement strict quality management systems (QMS) to ensure every component meets regulatory standards and design specifications without deviation.

Alignment with ISO 9001 and Strict Traceability

Compliance with ISO 9001 standards is the benchmark for medical device manufacturing, dictating rigorous risk management and process validation. A robust QMS ensures complete traceability from the raw material ingot to the final machined part. For example, when sourcing a China CNC turning service wholesale, it is crucial to verify that they maintain lot-specific documentation for every batch of medical-grade PEEK or Stainless Steel 316L. This documentation traces the material’s heat number, chemical composition, and mechanical properties, ensuring that in the event of a recall, every affected component can be identified immediately. Effective traceability protocols prevent the use of non-conforming materials, safeguarding both the manufacturer’s reputation and patient health.

Utilizing CMM and Non-Contact Scanning for Verification

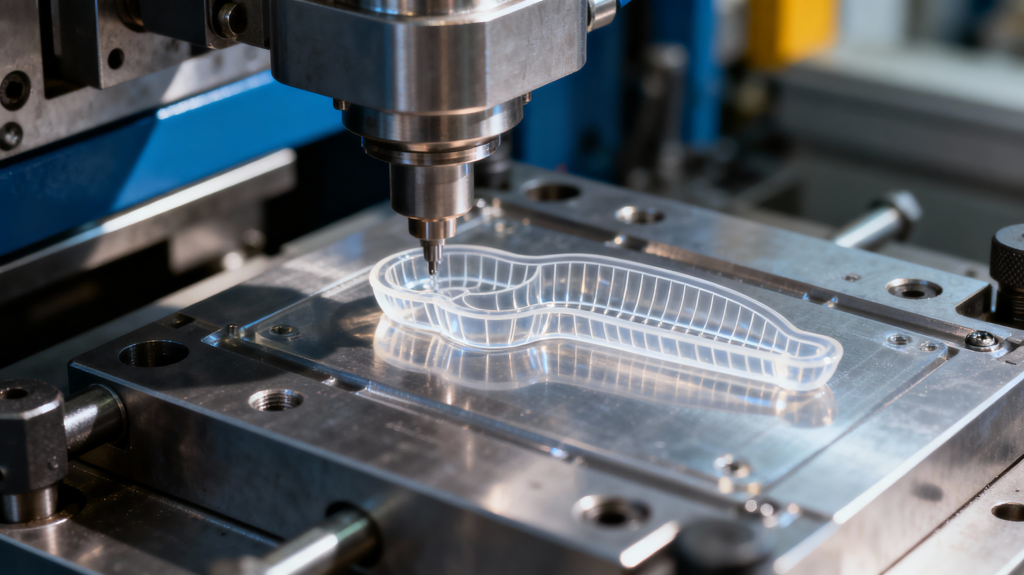

To verify micron-level tolerances, manufacturers employ advanced metrology equipment beyond standard calipers. Coordinate Measuring Machines (CMM) are used to probe complex 3D contours of orthopedic implants, verifying dimensions with sub-micron accuracy. For delicate or soft material parts, such as thin-walled plastic housings for diagnostic equipment, non-contact laser scanning creates a high-resolution digital twin of the physical part. This data is overlaid with the original CAD model to detect deviations as small as 0.002 mm. These verification processes are critical for ensuring that mating parts in surgical assemblies fit together with zero play, a requirement for the precise tactile feedback needed by surgeons during operations.

Livepoint Tooling: Precision Medical Manufacturing Capabilities

Livepoint Tooling stands as a strategic partner for medical device companies, offering over 23 years of expertise in high-precision manufacturing. Located in Shenzhen, Livepoint specializes in transforming complex designs into tangible realities through advanced CNC machining and injection molding. Their facility is equipped to handle the stringent demands of the medical sector, providing a seamless bridge between rapid prototyping and mass production.

Key Highlights:

Decades of Experience: With 23+ years in the industry, Livepoint has refined its processes to deliver reliable components for automotive, medical, and consumer electronics sectors.

Regulatory Compliance: Operating under an ISO 9001:2015 certified system, Livepoint aligns its medical manufacturing processes with ISO 13485 standards, ensuring rigorous quality control and full material traceability.

Advanced Facilities: The company utilizes cleanroom-capable environments for specific molding applications and high-precision CNC equipment to maintain tight tolerances for surgical instrument housings and internal gear components.

One-Stop Solution: From initial mold design and flow analysis to final surface treatments like painting and plating, Livepoint offers comprehensive services that reduce supply chain complexity.

Conclusion

Selecting the right manufacturing partner is critical for ensuring that medical devices meet the extreme precision, safety, and regulatory standards required for patient care. Whether you need a single prototype or high-volume production, Livepoint Tooling delivers the expertise and quality assurance necessary for success. Contact us today to verify your design feasibility and secure a reliable production solution for your medical components.